PRODUCERS OF GRANA PADANO D.O.P. SINCE 1959,

A FAMILY TRADITION IN ITS THIRD GENERATION.

Respect

The Consorzio di Tutela's branded mark, imprinted on each wheel of cheese, guarantees compliance with the DOP regulations at every stage of the production chain, from the field to the barn, the dairy and the maturing process. Inside, all the flavor of our land.

Territory

We source only and exclusively from local farmers to have 100% of our milk at zero kilometer.

Tradition

We add the wisdom and mastery of our cheesemakers to dose fragrance and flavor according to ancient tradition.

Passion

For over 70 years we have been supplying producers and wholesalers all over the world with our Grana Padano DOP.

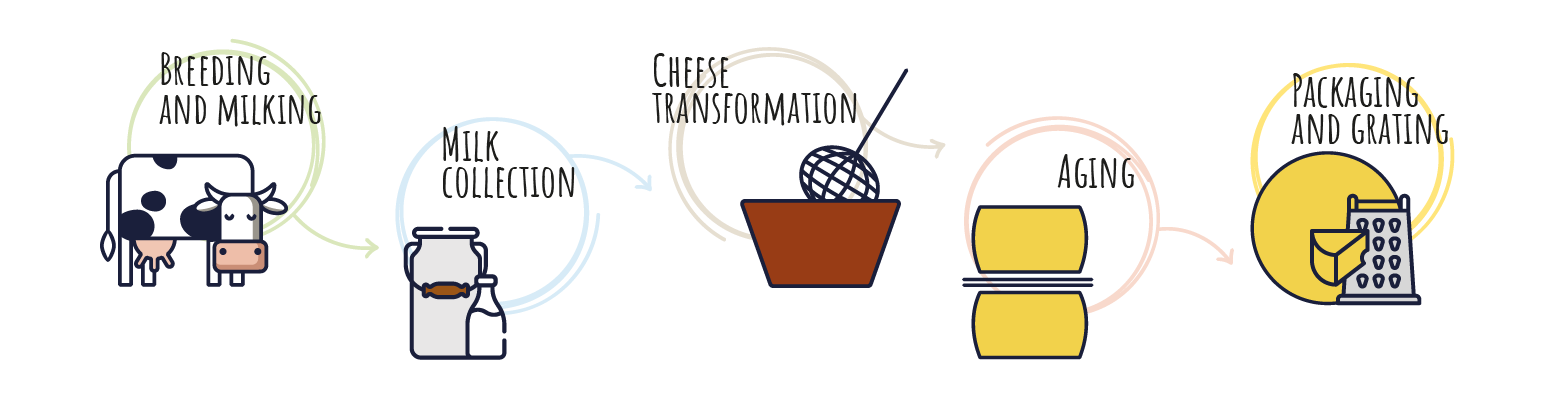

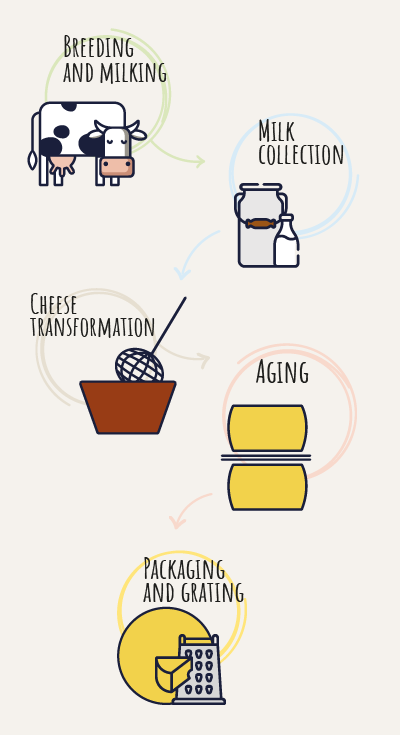

PRODUCTION

FROM THE TERRITORY COMES THE

MILK FROM OUR FARMERS

The milk is collected, analyzed upon receipt, left to rest for several hours in tanks and skimmed naturally before processing. Grana Padano is in fact characterized by being a semi-fat cheese.

THE MILK IS POURED INTO

DOUBLE-BOTTOMED COPPER POTS

The partially skimmed milk is poured into the 'cauldron'. Copper, as a thousand years ago when everything began, is still the protagonist of the production of this extraordinary cheese. The 'pot', shaped like an upside down bell, contains about 1,000 liters of milk and allows the production of two 'twin' wheels.

WHEY IS ADDED BY AUTOMATING THE

QUANTITY OF EACH INGREDIENT

The whey is added: the 'mother' of lactic ferments, which is reproduced every day, contains all the 'lactic bacteria' that will trigger fermentation in the fresh milk and give it its characteristic taste, aroma and fragrance many months later.

THE CHEESEMAKER CHECKS THE

RENNET AND LACTIC FERMENTS

In order to ensure that the transformation from milk to cheese takes place correctly, it is necessary to preserve the bacterial load at every stage. The cheesemaker therefore checks the rennet and uses lactic ferments to promote fermentation.

COOKING AND CURD EXTRACTION

The curd is broken by means of the 'spino', then steamed up to a temperature of about 53° C and under agitation. At the end of the cooking process the granules are deposited on the bottom of the boiler and, joining together, create the "shape".

THE WHEELS ARE

PLACED IN THE MOULD

The cheese is wrapped in cloths and placed in the mould which gives it its typical shape. The process lasts 24 hours and the cheese is turned every three hours and placed in a steel mould.

IMMERSION IN BRINE

Two days later, the cheese wheels are soaked in a solution of water and salt to complete the process of salting. This step can take from 14 to 30 days, depending on the final salting level. The wheels are then washed and dried.

MATURATION FROM 9 TO 20 MONTHS

Grana Padano DOP can be aged from a minimum of 9 months to over 20 months for Grana Padano d.o.p Reserve. Each wheel is cared for, cleaned and turned every 15 days at controlled temperature and humidity to obtain the perfect texture of flavor, aroma and taste.

SUSTAINABILITY

The word sustainability has its roots in the Latin, sustinere, which means to support, defend, take care. Sustainability for us means adopting a model of development that preserves nature's resources with care, avoiding waste.

We love our earth and we love to take care of it.

1.

WATER RECYCLING

AND RECOVERY

2.

ENERGY

SAVING

3.

SOLAR

PANELS

4.